EP UNIQUE

EP owns over 10,000㎡ plants and has a highly-skilled team of 60 employees providing one stop service to meet customers’ needs from manufacturing, technicians, to inspection process. With over a decade of experience, EP commits high quality products, lean manufacturing, and competitive prices.

Highly Skilled Staff

EP has a professional production crew consisting of highly skilled individuals with technical knowledge and prior manufacturing or material handling industry experience. Besides, EP offers training classes including how to control the welding quality, how to proceed with qualified inspection process for employees.

Strict Quality Control

Forks are essential to forklifts in order to function efficiently, and safe. EP strictly follows the necessary production processes and tests to assure the safety of each fork from the raw material to finished product. EP forks are designed and built according to ISO 2330 safety requirements.

Worldwide Market Coverage

EP forks are mainly made to supply the USA brands as well as to the EP Group. As of today, over 100,000 units of EP forklifts are manufactured and exported to customers around the world. EP wins good reputation for the forks in high quality.

PRODUCT OF EXCELLENCE

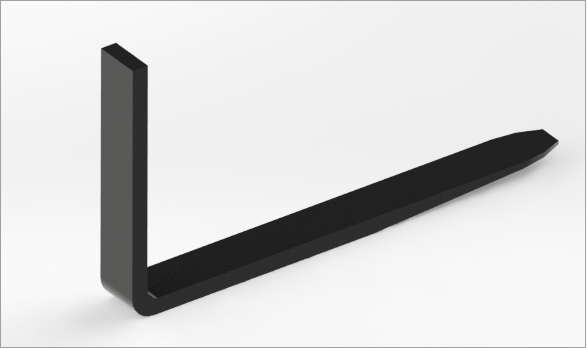

Blank Fork

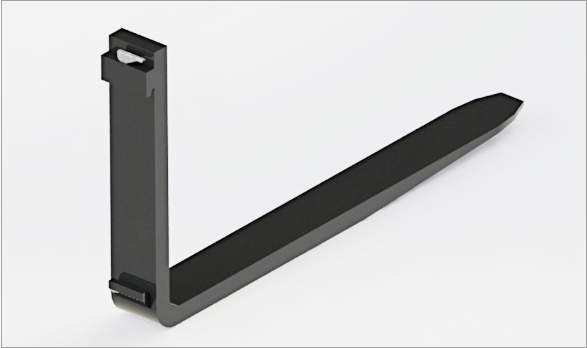

Pallet Fork

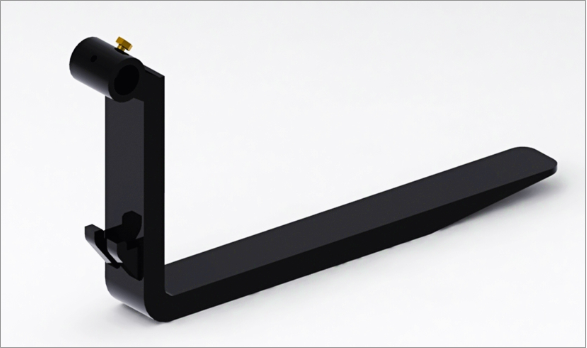

Shaft Fork

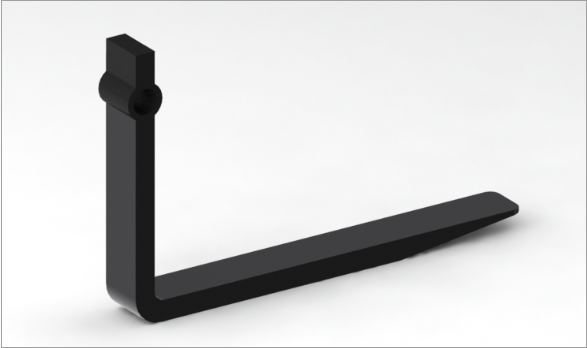

Straight Shaft Fork

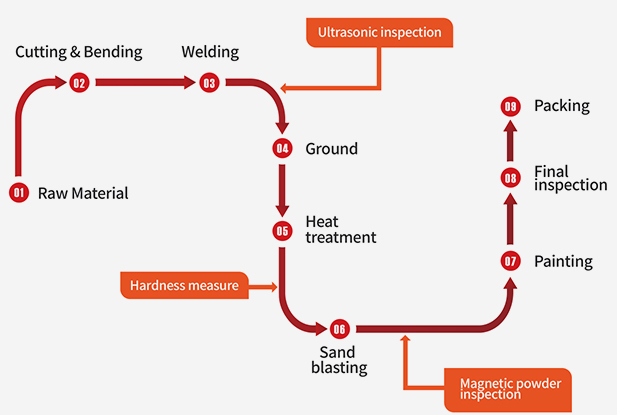

Production Process

EP always keeps the safety stock of raw materials for uncertainties in production demands. There are working instruction books for our workers to follow to keep the welding quality. What’s more, strength specifications will be met by 3 main key inspection processes, ultrasonic inspection, hardness measurement, and magnetic powder test during the production process.

Share